What is a clean bench?

What is a clean bench?

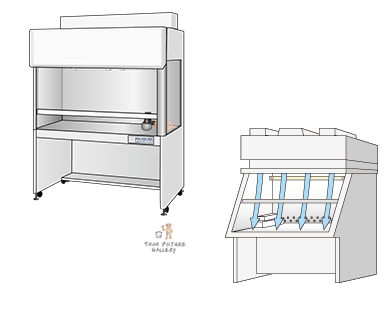

A clean bench is an enclosed workbench that is controlled to a certain air cleanliness level to prevent contamination such as dust, dirt, and airborne microorganisms. The clean bench can produce a high degree of air cleanliness locally in a room with a low level of air cleanliness by allowing the filtered clean air to flow directly to the item being worked on. The clean bench, basically, has a blower, a high-performance filter (HEPA filter, ULPA filter, etc.), and lighting, and some have such functions as water, gas, sink,, and exhaust as needed. The structure, performance, and test methods of a clean bench is specified in JIS B 9922.

The structure of a clean bench

The structure of a clean bench

The structure of a clean bench is specified in JIS B 9922 as follows:

- A)Structure that can be easily maintained, inspected and adjusted

- B)Walls in the work space do not easily peel or form rust

- C)Structure that prevents unfiltered air from entering the work space

- D)Structure that allows the clean bench to be connected to a ground wire

- E)HEPA or ULPA filter should be used as the main air filter

- F)Filter does not degrade or corrode easily under normal air conditions, and is easily detached for maintenance and/or replacement

- G)Structure of the main air filter mouting that does not leak aerosol over time

- H)For models that handle acids, organic solvents, biological particles, toxic gases, etc., structure that allows air containing such substances to be ventilated along the required exhaust route

- I)A clean bench with explosion-proof structure shall follow the requirements described in JIS C 0903

- J)For models that are equipped with both normal lighting and sterilization lamps, both types of lighting should not be lit at the same time without agreement between both shipping and receiving parties

Types of clean benches

Types of clean benches

There are several types of clean benches with various features added for work conditions

| Type | Features |

|---|---|

| Built-in type | Floor-standing units are built into equipment without the workbench. |

| Vibration-free type | This type has a gap between the workbench and the main unit, preventing the direct transmission of vibration. |

| Drying type | This type includes an infrared lamp for performing drying on the workbench. |

| Light table type | This type combines a fluorescent lamp with an acrylic or glass workbench. |

| Exhaust type | This type enables air exhaust from the workbench or a section of it. |

| Water supply/drainage type | The workbench or a section of it includes a sink with a faucet at the front. |

| Circulation type | This type circulates clean air. |

Pros and cons of a clean bench

Pros and cons of a clean bench

The clean bench sends clean air into the enclosed box-shaped device to make the inside of the device a positive pressure and push the air out. By doing so, dust and dirt (contaminants) are prevented from flowing in together with air from outside the device. On the other hand, due to the enclosed structure, it is necessary to work with only the hands inserted, so it is not suitable for a kind of work in which a lot of things are put in or taken out, or one in which a worker has to bend over an item being worked on.